Mountnessing Windmill

Mountnessing Windmill is a restored post windmill constructed during the Napoleonic Wars. It is open six days a year and offers milling demonstrations during optimum weather conditions.

Key info

| Location | Roman Rd, Mountnessing, CM15 0UG |

| County | Essex |

| Completed | 1807 |

| Constructed by | William Bentall |

| Maintained by | Essex County Council & Friends of Mountnessing Windmill |

| Heritage category | Listed Building Grade II* |

Visiting guide

Check opening times

Free entry

Free car park

Is Mountnessing Windmill open regularly?

Mountnessing Windmill is open specific days of the year. Visit the windmill Facebook page for more information.

What can I expect when visiting Mountnessing Windmill?

Starting from the car park, you will immediately receive a view of the entire mill sitting on its artificial mound. The sails are of the type known as spring sails and are semi-automatic in operation.

Head round the back through the door to the red brick roundhouse. Here we can see the crosstrees resting on four brick piers, which supports the central post. The post is the main support for the mill above as it rotates towards the direction of the wind.

Look up to view the quarter bars, which are mortised into the post at the top and slope down in pairs to meet the ends of the horizontal crosstrees. These timbers were crafted from elm, a robust material that doesn’t split easily when under tension from mechanical movement.

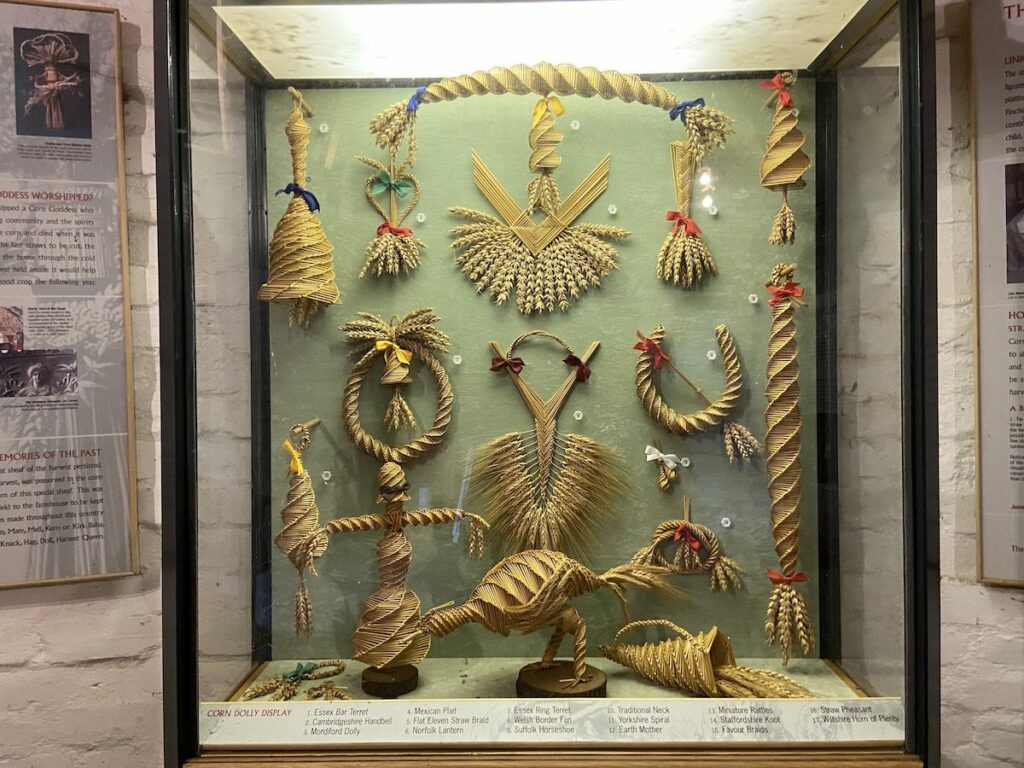

There are many display boards, models, and items of interest in the roundhouse. We particularly enjoyed the corn dolly exhibition. These figures are fashioned from straw and stem back to pagan times when people who worked the land worshipped corn goddesses in the hopes of protecting their harvest. Other items such as wreaths were also made.

Exit the roundhouse and head to the back of the mill where you will see the steps leading up. Notice the protruding tail pole, which is pushed to rotate the mill.

Enter the spout floor, this is where the miller would have spent most of their working day. You will see the post directly in front attached to the crown-tree above. On the left scales used to measure fine and coarse flour from the wire machine above. Once weighed, the flour sack would have been tied and slid down the tail steps to the ground below.

Head to the back of the room and look up for a view of the great spur wheel in the centre with two smaller gears called “stone nuts” either side, which are used to raise and lower the bedstone above.

Look up at the beams supporting the floor above. Notice the joist grooves that seemingly have no purpose? This evidence suggests the wood may have been sourced from a ship. Recycling construction materials in the early 19th century was very much a common occurrence. The white canvas chutes behind delivered flour from the wire machine above.

Head up the stairs to the stone floor where the grinding happens. On the floor are two wooden “tuns” or “vats” that each encase a pair of millstones, made from French Burr, an ideal stone for grinding wheat, which was a staple of the local agriculture. Above each tun is a wooden trestle or “horse”, which supports a wooden tapered box or “hopper” that is fed via a canvas chute with grain from the bins above.

Behind the tuns is a large, cogged wheel known as the brake wheel. It is attached to the windshaft that is connected to the sails outside. The wooden blocks around this wheel for the brake to stop the sails when required. The smaller horizontal wheel at mounted to the bottom of the brake wheel is known as the “wallower”. This bevelled gear drives the millstones by transferring power to the great spur wheel below via an upright shaft.

Notice the exposed millstone taken out of its tun and its cross sections. The chisel was used to “dress” the millstone, a maintenance process where the surfaces are smoothed, and a pattern of grooves is cut to assist grinding. Behind the millstone is the wire machine, a mechanical sieve that separates the bran from the meal producing a refined flour. The bran was used as animal feed.

Head up the next set of stairs to the top floor for a view of the grain bins where meal is added. Above is the sack hoist that is powered by the sails. The hoist uses a chain to reach the roundhouse below through a series of trap doors.

How long does it take to visit Mountnessing Windmill?

It will take you around 40 minutes to complete a tour of the windmill during an open day.

Is Mountnessing Windmill suitable for a picnic?

The windmill is located in an open green space, which is suitable for a picnic.

How do I get to Mountnessing Windmill?

There is a car park by the windmill if you are arriving by car. A bus stop is located a stone’s throw away on Roman Road with services to and from Brentwood. Ingatestone railway station is 1.5 miles away, then it’s a short bus journey to the windmill.

History of Mountnessing Windmill

1674 – A windmill on this site was first mentioned in John Ogilby’s strip map of the London to Harwich road. This means the mound upon which Mountnessing Windmill stands is older than the mill itself.

1807 – The year 1807 can be found painted on the crown-tree indicating Mountnessing Windmill was most likely completed during this year by William Bentall, a farmer and mill owner from Felsted. When the mill was complete, Joseph Agnis was assigned as the miller via a lease.

1819 – William Bentall sold the mill, with the going gears, utensils, and implements to Joseph Agnis for the sum of £450 (£27,541 in 2021).

1850 – Joseph Agnis gives the mill to his son Joseph the younger for the purposes of advancing his son in the world.

c.1890s – A portable steam engine was installed in a nearby low building on the edge of a large pond, which no longer exists. It was manufactured by Wedlake and Denby of Hornchurch and drove a separate set of stones when there was insufficient wind to turn the windmill’s sails.

1908 – Joseph Agnis dies, his relative, Robert Agnis renews the lease of the land upon which the windmill stood and employs Joseph Doe as miller.

1914 – The windmill is repaired.

1915 – Robert’s relative Walter Walker Agnis, a miller from East Horndon, extends the lease by 14 years at Mountnessing and became the last serious user of wind power. He disposes of the rats in the thatch and installed two hedgehogs in the roundhouse to prey on insects attracted to grain.

1917 – The windmill is repaired again.

1924 – The steam engine was replaced by a paraffin engine. The windmill gradually went out of use by this year.

1932 – Walter’s son Leonard Agnis had developed a taste for windmilling while helping his father to work the mill. Leonard brings Mountnessing Windmill back into operation once more and continues to work the windmill occasionally until a sail was lost, the mill then became derelict. Walter then dies and the ownership of the windmill is passed to his widow Emily.

1938 – The windmill was in poor condition. It was acquired by Mountnessing Parish Council including the land around the mill. The windmill was restored externally and playing fields were created on the land to mark the coronation of King George VI.

1947 – The windmill receives a preservation order protecting it from demolition; however, the parish council under the direction of residents sells it to Essex County Council for the nominal sum of one shilling due to the rising cost of repair [1].

1952 – Mountnessing Windmill is first designated as a listed structure [2].

1956 – A new set of sails was fitted.

1969 – A pair of the sails were renewed.

1974 – The other pair of sails were renewed; however, by this time, the roof of the windmill was leaking, and its fabric had weakened badly. The Friends of Mountnessing Windmill is formed from members of Brentwood Civic Society to raise funds and collaborate with the county planner and millwright for restoring the mill.

1975 – The first open day is held, 50 people braved the rain and biting wind to attend.

1976 – The brickwork of the roundhouse was repaired, and two new doors fitted by volunteers.

1980 – The new windmill roof was built on the ground and lifted into position by crane.

1981 – The mill was engulfed by scaffolding and encased in plastic sheeting for protection against the weather.

1982 – Work was sufficiently advanced to enable the reconstruction of the milling machinery, which had suffered badly at the hands of vandals who stole many smaller parts. Many parts had to be created from scratch with the aid of old photographs and the examination of nearby mills.

1983 – The restoration of Mountnessing Windmill is complete, and it is officially opened and set in motion.

1984 – The restored mill was opened to the public for the first time [1].

Sources

- Wooding, R., Pargeter, V. and Sier, B. (1994) Mountnessing Windmill a history and description. Chelmsford: Essex County Council.

- Historic England (2020) Mountnessing Windmill. Available at: https://historicengland.org.uk/listing/the-list/list-entry/1293205 (Accessed: 23 September 2022).

Bewdley Museum

Bewdley Museum